For detailed information, other images and documents, please select individual articles from the following table.

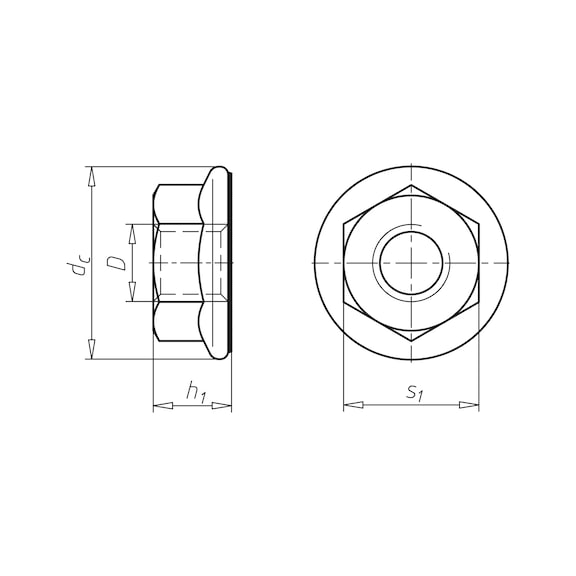

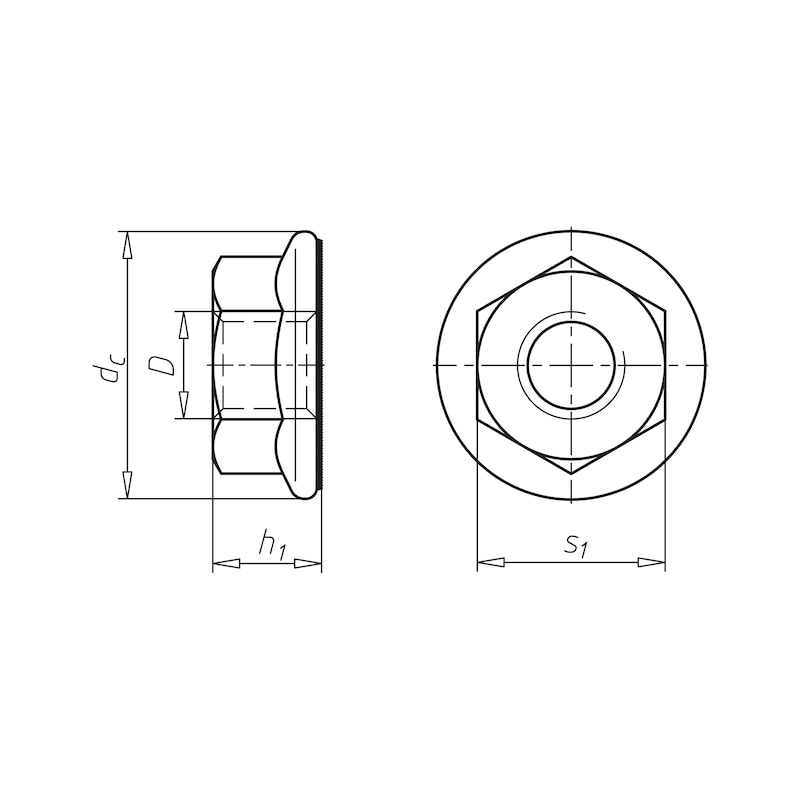

Ribbed nuts Zinc-nickel, transparent passivated with sealing for frame screws

From M12 with fine thread

Register now and access more than 20,000 products

Variants

Register now and access more than 20,000 products

From M12 with fine thread (thread pitch 1.5 mm)

Chromium(VI)-free

Complies with the EU End of Life Vehicles Directive

Corrosion resistance

Approx. 720 hours of base metal corrosion according to DIN EN ISO 9227-NSS

The specified corrosion resistances apply for the corrosion tests according to DIN EN ISO 9227-NSS (salt spray mist testing), at the earliest 24 h after coating in the “as coated” state, i.e. before sorting, packaging, transporting and/or assembly. These values can be reduced through inevitable handling and assembly processes. A transfer of the corrosion resistances from the salt spray mist test to real assembly and operating conditions is not possible in the majority of cases. When designing a connection, both the combined materials and any coatings and the environmental conditions during operation must be considered by the designer when selecting a suitable corrosion protection coating.

Working principle of locking ribs:

During tightening, the locking ribs roll the counter-material in the area of the nut contact surface. This causes a plastic deformation that hardens the surface. No significant settling is determined at the end of tightening. The locking ribs limit the amount of settling of the connection and therefore reduce the loss of pretensioning force.

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!