For detailed information, other images and documents, please select individual articles from the following table.

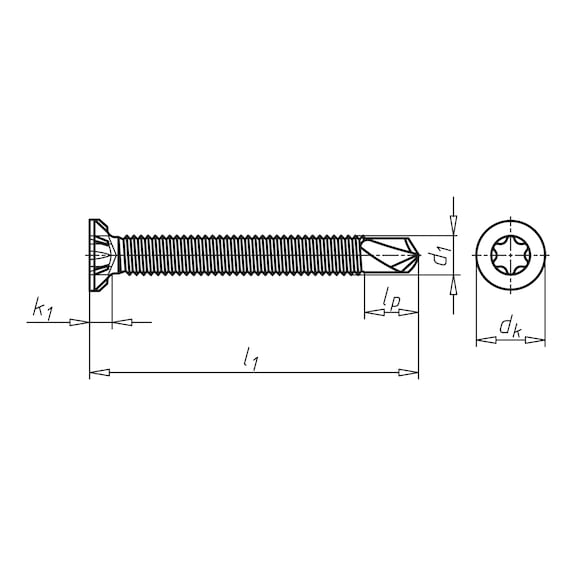

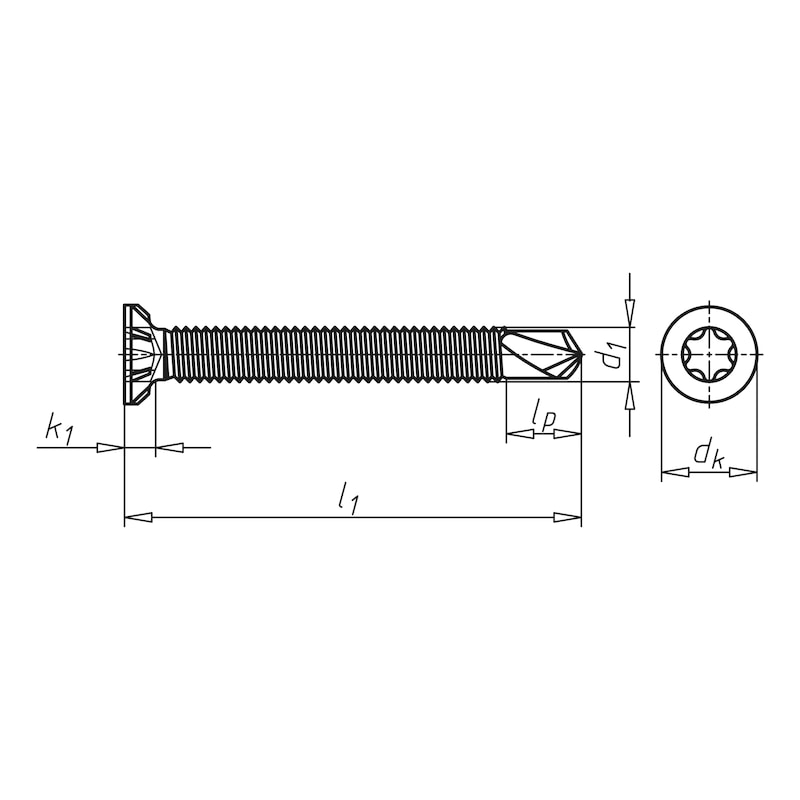

Window construction screw, self-drilling, countersunk milling head, FEBOS®plus Steel, zinc-plated, blue passivated, AW drive

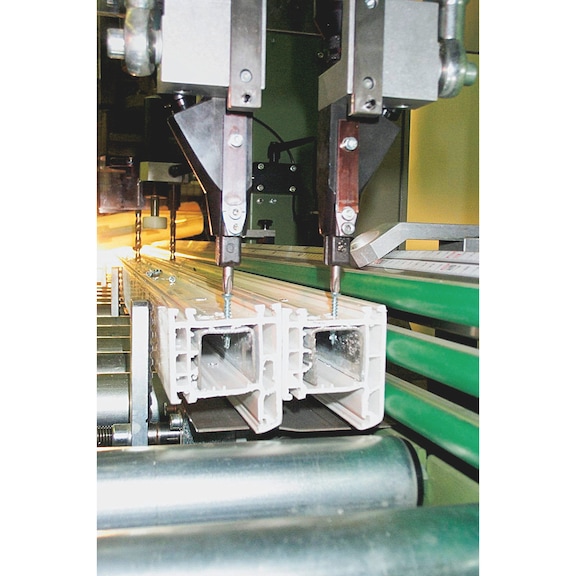

For use in automatic systems, roller-sorted

Register now and access more than 20,000 products

Variants

Register now and access more than 20,000 products

- Metric thread

- Head diameter 7.0 mm

- Self-drilling window construction screw for use in plastic window construction

- For connecting plastic profiles with the metal reinforcement (up to 2.5 mm) and for securing fittings on profiles with metal stiffening (up to 2.5 mm)

- More load-bearing thread turns for thin iron reinforcements

The danger of forced feed with large distances between plastic and metal stiffening is minimised by the flat metric thread

If a forced feed occurs, the drill tip can tear out or the screw can break during processing.

AW drive

- Optimum transmission of forces

- No ejection forces

- Good centring

- Fast location

Please also note the information on the overview page.

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!