For detailed information, other images and documents, please select individual articles from the following table.

Plastic anchor with screw W-UR F 8

Extremely versatile frame anchor with ETA approval. Tested and approved for over 90 types of stone and autoclaved aerated concrete. With A4 stainless steel countersunk head screw

Register now and access more than 20,000 products

Variants

Register now and access more than 20,000 products

- With countersunk head screw, A4 stainless steel

- Can be installed directly

- Immediate load-bearing capacity, no waiting

- Low insertion torque of the frame anchor; slight expansion of the anchor with little movement of its sleeve

- 2 insertion depths (hnom = 50 + 70 mm): Concrete >= C12/15; solid brick >= Mz 10 (>= NF); vertically perforated brick >= HLz 8 (>= 2DF); solid sand-lime brick >= KS 10 (>= NF); hollow sand-lime brick >= KS L 6 (>= 2DF); hollow sand-lime brick >= KS L 6 (>= 12DF); solid bricks of standard concrete >= Vbn 10 (>= NF); solid lightweight concrete bricks >= V 2 (>= NF)

- Expands in four directions: high load-bearing capacity

- Increased force transmission: Even, continuous load distribution across the entire expansion area

- Universal frame anchor (concrete, perforated and solid brick masonry, aerated concrete)

- The internal notch prevents premature spreading of the anchor during installation

- Pre-assembled anchor sleeve and special screw for easier installation

- Type W-UR F anchor does not require an additional U-washer and prevents contact corrosion

- Improved force transmission in hollow and solid construction materials; anchoring by friction locking between the anchor sleeve and the support

W-UR 8, W-UR F8 (galvanised steel, stainless steel): General technical approval Z-21.2-1838

W-UR 8 and W-UR F 8 (galvanised steel, stainless steel): European technical approval ETA-08/0190

Anchor sleeve made of high-quality polyamide

Fire resistance W-UR 8: Concrete: Tensile and transverse loads, R30, R60, R90, R120 (according to technical report TR 020) Masonry tensile load: F30 (solid sand-lime brick, solid brick, hollow sand-lime brick) Transverse load: F30, F60, F90, F120 (vertically perforated brick, hollow sand-lime brick, solid brick, autoclaved aerated concrete)

Notice:

Drill perforated and hollow blocks with a rotary drill (without impact mechanism)

For anchoring in solid bricks and solid sand-lime bricks, we recommend that you perform pull-out tests due to the differences in brick manufacturing.

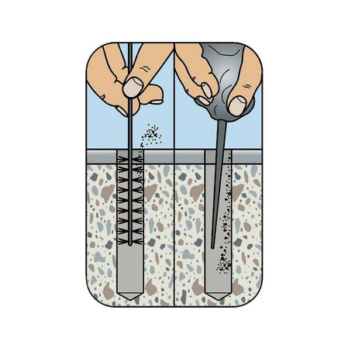

Drill cuttings must be removed from the drill hole

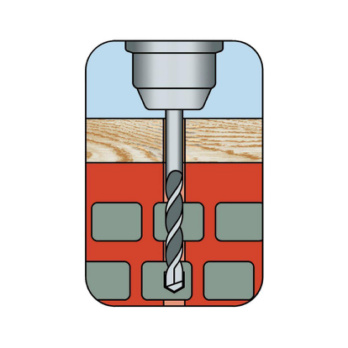

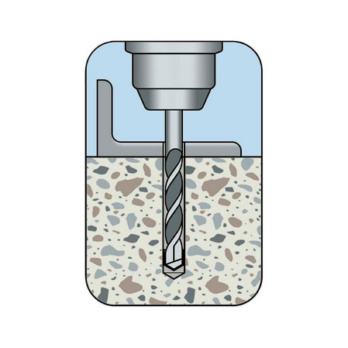

Create the drill hole

Create the drill hole

Clean the drill hole

Clean the drill hole

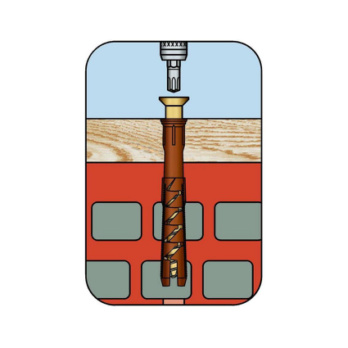

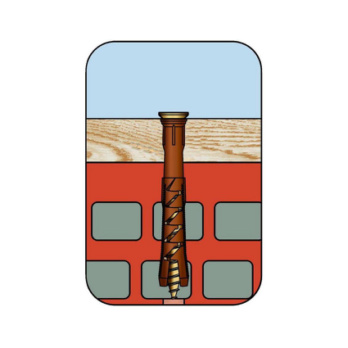

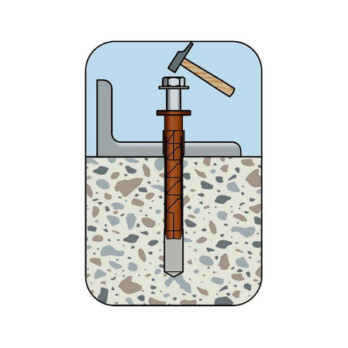

Set anchor and screw

Set anchor and screw

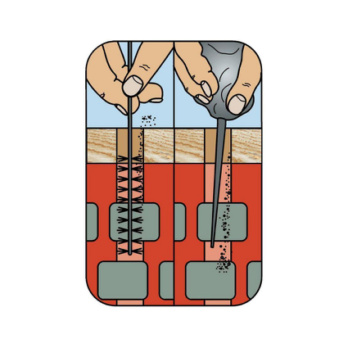

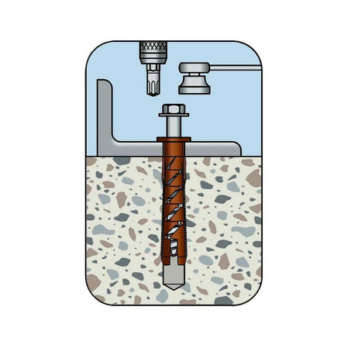

Screw in the screw

Screw in the screw

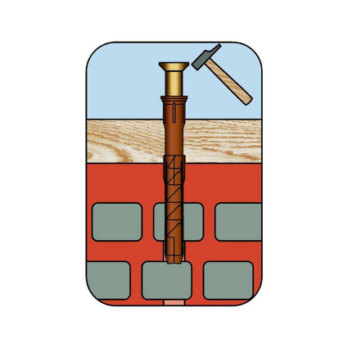

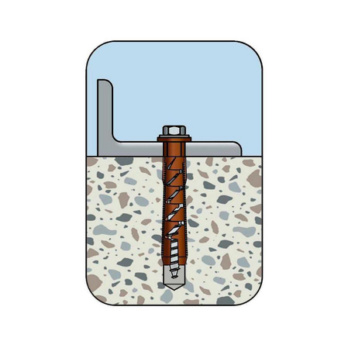

Screw in screw until flush

Screw in screw until flush

Create the drill hole

Create the drill hole

Clean the drill hole

Clean the drill hole

Set anchor and screw

Set anchor and screw

Screw in the screw

Screw in the screw

Screw in screw until flush

Screw in screw until flush

W-UR 8, W-UR F8 (galvanised steel, stainless steel): General technical approval Z-21.2-1838

W-UR 8 and W-UR F 8 (galvanised steel, stainless steel): European technical approval ETA-08/0190

Anchor sleeve made of high-quality polyamide

Fire resistance W-UR 8: Concrete: Tensile and transverse loads, R30, R60, R90, R120 (according to technical report TR 020) Masonry tensile load: F30 (solid sand-lime brick, solid brick, hollow sand-lime brick) Transverse load: F30, F60, F90, F120 (vertically perforated brick, hollow sand-lime brick, solid brick, autoclaved aerated concrete)

The anchor has European Technical Approval (ETA) for use in multiple connections of non-load-bearing systems (e.g. frames, suspended ceilings etc.).

W-UR and W-UR F can be anchored to the following supports: Standard concrete, masonry walls (solid brick, solid sand-lime brick, vertically perforated brick, hollow sand-lime brick, hollow lightweight concrete blocks, solid bricks and solid lightweight concrete blocks, concrete bricks, autoclaved aerated concrete), brick ceilings, prestressed hollow concrete slabs, reinforced autoclaved aerated concrete, plasterboard panels

Installation temperatures:

Support temperature: >= -40 °C

Anchor sleeve temperature: >= 0 °C

The stainless steel screw can be used outdoors, in industrial environments and in coastal areas

Suitable for attaching frames, ceilings and ceiling substructures (made of wood or steel), wooden beams, wooden slats, metal brackets, metal rails, suspended ceilings, cable ducts, angle brackets, profiles, wall-mounted cabinets, shelves etc.

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!