For detailed information, other images and documents, please select individual articles from the following table.

HSS annular cutter

Standard annular cutter made from HSS for drilling large through-holes up to 50 mm in diameter with mobile magnetic or stationary drills in conventional steels up to 850 N/mm², wood and non-ferrous metals, such as aluminium, aluminium alloys and plastics.

Register now and access more than 20,000 products

Variants

Register now and access more than 20,000 products

High performance and rapid drilling progress with a long service life

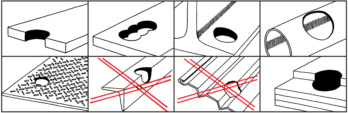

In contrast to solid drilling, only a thin metal ring is cut. The drill core is ejected by an ejector pin.

No pre-drilling required, no formation of burrs

No pre- or post-processing required

Optimised cutting geometry

- Long service life compared to many standard core drill bits

- Clean drill profile

- Drill hole with precise tolerances

Precise guidance, no slipping

Suitable for overlap drilling. Problem-free drilling on curved surfaces and pipes.

- Unlike twist drill bits, the annular cutter only machines a thin ring of material rather than the complete bore diameter. The drilling core is removed using a pilot pin with spring power, which is not included in the scope of delivery. Annular cutters therefore offer a drilling time that is 10 times faster than twist drills bits.

- Sufficient continuous cooling during the entire drilling process considerably increases the service life of the annular cutter. Do not use dry.

- Not suitable for press chipboard, titanium or heat-resistant and high-alloy steels

- For materials and cutting value parameters, see the summary overview tables

- Wear appropriate protective equipment, such as eye protection, hearing protection devices and protective gloves

- Take off loose clothing or jewellery which could get caught in the moving parts

- Annular cutters must not be used with hand-held tools

- Before use, ensure perfect concentricity and the correct clamping function of the tool drive

- With Weldon shank ∅ 19 mm for use on mobile magnetic drills or stationary drills for creating large holes with a diameter of up to 50 mm and a cutting depth of 30 mm or 50 mm

- Fein drills with QuickIn mount can be used with an adapter

- Application on stationary drills with Morse taper is possible using the appropriate mount holder

- Insert the ejector pin into the core drill bit

- Push the core drill bit into the mount holder of the drill unit and tighten the hexagon socket screws

- The core drill bit is automatically locked into place when using quick-action mounts

- Make sure the core drill bit is sitting cleanly in the mount

- Putting the drill under lateral load during use may cause the tool to break

- Fix the drill unit into the right position for drilling — make sure the drill unit has a stable footing

- If necessary, secure the drill unit before drilling using a safety strap, especially for use on vertical surfaces and overhead work

- Pay attention to the speed table and use coolant

- Drill carefully (without centre punching and pre-drilling), pay attention to an even feed and even rotation speed throughout the entire drilling process

- Remove chips and drill core after each drilling operation

- Caution: Risk of injury, chips and drill core may be very hot and sharp

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!