The images are examples. For detailed information, other images and documents, please select individual articles from the following table.

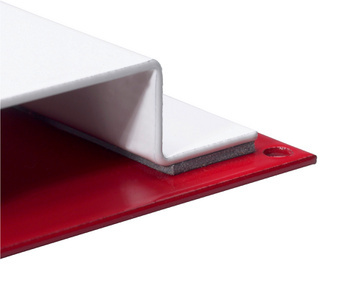

Power mounting tape

Universal double-sided, highly adhesive tape for demanding assembly bonding indoors and outdoors. Connects and seals in a single step.

Register now and access more than 20,000 products

Variants

Register now and access more than 20,000 products

Extremely high and long-lasting adhesive strength

Per running metre, holds up to:

- 8 kg/25 mm width

- 6 kg/19 mm width

- 4 kg/12 mm width

Invisible connections possible

- Optimum design without any unappealing holes, screws, rivets etc.

- Material is not weakened by drilling, riveting etc.

2 in 1: Bonds and seals in a single step

- Immediate, stress-free bonding

- Provides vibration- and shock-absorbing effect

- Prevents rust formation

Excellent moisture- and UV-resistance for possible use outdoors or in damp rooms.

Please familiarise yourself with the applicable building regulations, which may differ from region to region, before using the adhesion solutions presented and also comply with them when designing and executing your application. We recommend that you always use mechanical safety measures for adhesive bonding above head height (1.80 m).

| Base material table for transparent mounting tapes | |||

| Power PLUS mounting tape | Power mounting tape | ||

| 0894905012 0894905019 0894905025 | 0894909008 0894909009 0894909025 | ||

| Brick (cut surface) | ⎷1 | ⎷1 | |

| Fired brick | ⎷2 | ⎷2 | |

| Sand-lime brick | ⎷2 | - | |

| Beech | ⎷3 | ⎷3 | |

| Spruce | ⎷3 | ⎷2 | |

| Larch | ⎷3 | ⎷3 | |

| Other | Glass | ⎷4 | ⎷4 |

| Bituminous substrates | - | - | |

| Silicone | - | - | |

| Plastics | PMMA | ⎷3 | ⎷3 |

| ABS | ⎷2 | ⎷2 | |

| PC (polycarbonate) | ⎷3 | ⎷3 | |

| PVC | ⎷2 | ⎷2 | |

| Polyethylene (PE) | - | - | |

| Polypropylene (PP) | - | - | |

| Teflon (PTFE) | - | - | |

| EPDM | - | - | |

| ⎷1 = Limited adhesion ⎷2 = Moderate adhesion ⎷3 = Good adhesion ⎷4 = Very good adhesion ⎷5 = Excellent adhesion - = No adhesion | |||

| Metal | Aluminium | ⎷5 | ⎷4 |

| Steel | ⎷4 | ⎷5 | |

| Wood and stone | Concrete | ⎷5 | ⎷4 |

| Granite | ⎷4 | ⎷4 | |

| Marble | ⎷2 | ⎷3 | |

The usage instructions are recommendations based on the tests we have conducted and on our experience; carry out your own tests before each application. Due to the large number of applications and storage and processing conditions, we do not assume any liability for a specific application result. Insofar as our free customer service provides technical information or acts as an advisory service, no responsibility is assumed by this service except where the advice or information given falls within the scope of our specified, contractually agreed service or the advisor was acting deliberately. We guarantee the consistent quality of our products. We reserve the right to make technical changes and further develop products. Please observe the technical data sheet!

Power mounting tape is used to connect similar and different materials, such as uncoated metals (e.g. steel or aluminium without oxide layer), compact and hard wood*, glass, high-energy plastics (ABS, polycarbonate, PMMA, hard PVC etc.). It is suitable for smooth and textured, sufficiently solid surfaces. Compared to other connection systems, it is characterised by its fast and efficient processability.

Not recommended for use on low-energy materials such as PE, PP, powder coatings, Teflon® or hard-to-glue surfaces, for example, PA, rubber, silicone, soft PVC, EPDM etc. Adhesion may be impaired on painted surfaces.

*Caution when using with wood, its constituent compounds may influence the level of adhesive strength

Auto/cargo:

Sensors, adhesion of cover panels of all types, e.g. reflectors, mirror glass, decorative mouldings, ceilings, bumpers etc.

Metal/building services:

Bonding cable ducts, mounting signs, glass elements, grab handles, metal trim and base plates for doors and lifts, plastic parts for neon advertising.

With dome lights, conservatories etc., consider the various thermal expansion properties of the specific materials in use.

Plumbing:

Mirrors, brackets, decorative elements, dispenser systems etc.

Wood/construction:

Metal profiles in façade construction, glass and plastic parts for dome lights and conservatories, window and door bars etc.

Maximum holding power is only achieved under optimum processing conditions. Power double-sided mounting tape holds on most smooth or lightly textured, sufficiently solid surfaces where a processing temperature of over 10 °C is maintained. Lightly sanding can improve the adhesive strength. Any oxide layers on metals are also removed. Always thoroughly remove any sanding dust before bonding. Do not use compressed air that contains oil. Please also refer to the technical data sheet.

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!