The images are examples. For detailed information, other images and documents, please select individual articles from the following table.

SHARK UR plastic frame fixing, flat collar with A4 stainless steel hexagon head bolt

Universal frame fixing with special anchor geometry and immediate load-bearing capacity with ETA assessment for over 100 building materials

Register now and access more than 20,000 products

Variants

Register now and access more than 20,000 products

Reliable and versatile

- Part of the SHARK UR product family, which has been tested for more than 100 proven and modern building materials in total as part of ETA-08/0190

- The diameters 8 and 10 are tested and approved for a total of 105 different base materials

- Improved safety with expert assessment on fire behaviour in concrete and masonry

Excellent stability

- Due to the anchor geometry, the teeth expand in four directions and claw into the base material

- Anchorage via friction locking between anchor sleeve and base material

- High working loads due to expansion in four directions

- Improved load transmission through even, continuous load transfer across the entire expansion area

- Virtually no spinning of the anchor sleeve due to low installation torque and expansion

- Anchor sleeve made of high-quality polyamide

- Very strong anti-rotation lock

Space-saving fastening

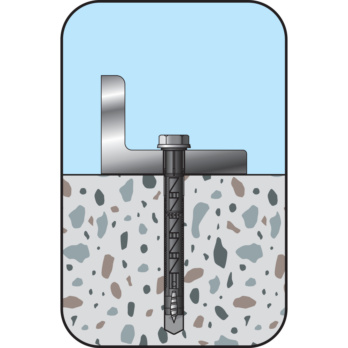

- Time savings due to immediate load-bearing capacity

- Minimal installation work because the anchor sleeve and special screw are pre-assembled

- Hammer-in stop prevents premature expansion of the anchor during installation

Embedment depths

- Two embedment depths in defined building materials

- SHARK-UR F 10 (zinc plated steel, stainless steel): European technical assessment ETA-08/0190

- Expert report on fire resistance period in the event of fire exposure

Metal substructures

Metal substructures

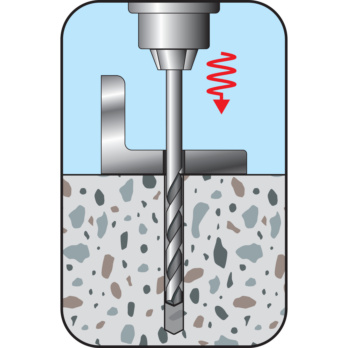

Drill the hole

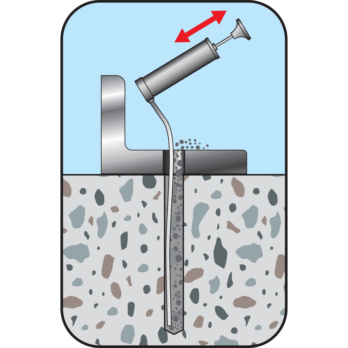

Remove drill cuttings

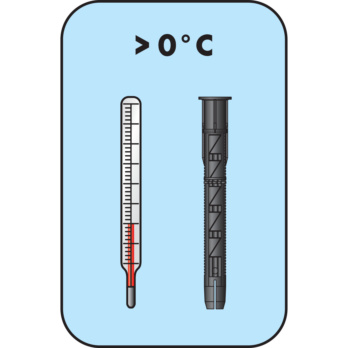

Check temperature of anchor sleeve

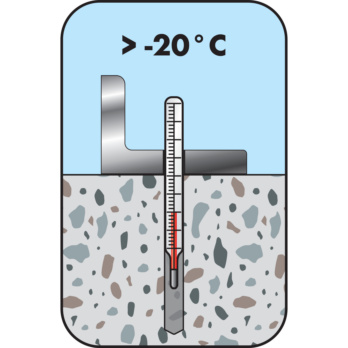

Check temperature of substrate

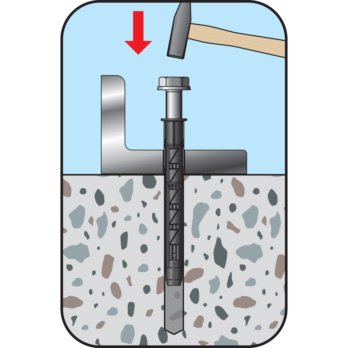

Install the anchor and screw with a hammer

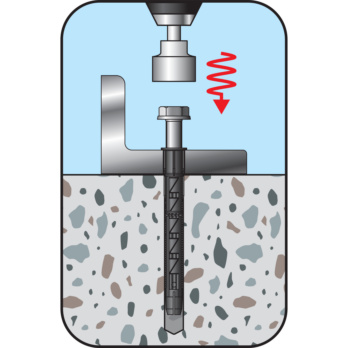

Screw in dowel

Screw in screw until flush

- SHARK-UR F 10 (zinc plated steel, stainless steel): European technical assessment ETA-08/0190

- Expert report on fire resistance period in the event of fire exposure

- The anchor can be used with a European technical assessment (ETA) for anchors in a redundant non-structural system in non-load-bearing systems (e.g. façades, suspended ceilings etc.)

- Approved by ETA assessment for over 100 building materials such as various bricks, including solid and perforated bricks, hollow sand-lime and solid sand-lime blocks, solid concrete and perforated blocks, hollow lightweight concrete blocks

- Suitable for normal weight concrete masonry walls such as solid brick, solid sand-lime blocks, vertically perforated brick, hollow sand-lime blocks, hollow lightweight concrete blocks, solid lightweight concrete blocks, concrete and autoclaved aerated concrete bricks

- Suitable for fastening façade, ceiling and roof substructures (made of wood or steel), wooden beams, wooden laths, metal brackets, metal rails, suspended ceilings, cable conduits, angle brackets, profiles, wall-mounted cabinets, shelves etc.

- Suitable for outdoor and wet room applications due to the A4 stainless steel hexagon head bolt with pressed-on washer

- Suitable for fastening where proof of load-bearing capacity under exposure to fire is required

- Drill perforated and hollow concrete blocks with a rotary drill (without hammer mechanism)

- Drill cuttings must be removed from the drill hole, e.g. with blow-out pump art. no. 0903990001

- Drilling in concrete with a dust extraction drill bit means there is no need to clean the drill hole

- Installation temperature in base material ≥ -20 °C

- Installation temperature of the anchor sleeve ≥ 0 °C

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!